We are HYPROmill

An innovative production and trading company focusing on automation in manufacturing industry.

Familiarization with a project

At first, we look at requirements of our client, identify their needs and then we begin to create first designs. We prepare visualisation of a project in Creo Elements software for a client.

Maximum precision

Within construction and projection, we are able to create a 3D model with calculations, simulation and a complex solution. As soon as a design is approved, an implementation process and assembly at a client begin.

Flexibility

Working a project out depends on its complexity, production availability or delivery time of components. We are able to be flexible in unexpected situations due to our long-term professional experience and own production.

We can help you with…

Our team is competent to solve every idea or dilemma in your production. HYPROmill realizes your ideas in 3D visualisations and consequently secures production and assembly.

Design, production, assembly, supply of sensors and actuators, robotic workplaces, electrical switchboards

Developing PLC programs and HMI visualization

Design, modification, safety fences, covering and installation of safety circuits of machines and devices

Single-purpose machines, welded constructions, shelving systems

Manipulators, conveyor systems, fully automated conveyors, production lines

3D scanning and much else…

Production and references

Welded constructions

– a construction design

– static conversions

– 3D visualizations

– production and assembly

3D scanning

– scanning in all sectors of engineering industry

– scanning by a FARO scanner

Machines and automated workplaces

– a concept, a construction design and 3D visualisation

– production, assembly and programming

– CE marking

Commercial products

– Design according to client requirements

– Ensuring final production

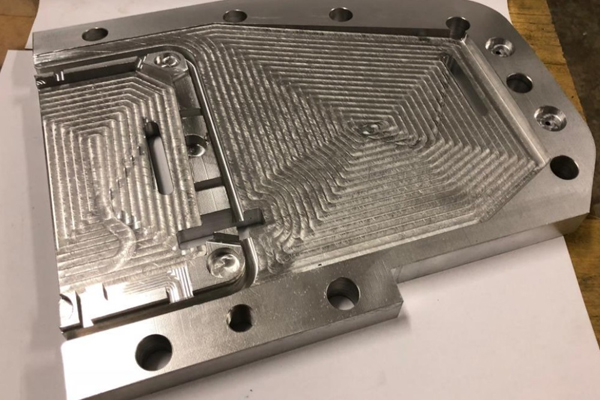

Engineering production

CNC milling 3-axis CNC milling machines

Travels: X 1270 mm, Y 508 mm, Z 635 mm

Prototype components for:

– single-purpose machines,

– assembly jigs,

– welding jigs, welding lines, welding workplaces,

– clamping and measuring jigs,

– measuring and testing devices,

– any prototypes in accordance with provided documentation.

We machine all kinds of technical materials:

– aluminium and its alloys

– copper and its alloys

– steel

– plastics

– stainless steel

– composites

Turning

– CNC turning up to length of 3000 mm

– a diameter over the tool head – 350 mm

– a standard lathe up to length of 2000 mm

– max. weight – 500 kg

External grinding of rotating parts

– up to length of 3000 mm and a diameter of 400 mm

– up to weight of 300 kg between centers

– grinding of quenched and nitride materials,

– grinding of stainless steel and soft materials

Bore grinding

– up to a diameter of 20 mm; smaller diameters may be considered after a consultation

– the maximum diameter of a workpiece – 400 mm

– bores up to the maximum length of approx. 450 mm

– clamping in chucks up to weight of 50 kg

Groove and tooth machining

– the maximum length of a workpiece – 3000 mm

– the maximum diameter – 250 mm

– grooving according to DIN5480; other possibilities may be considered after a consultation

Heat treatment

– we secure induction hardening, case-hardening, nitriding and vacuum hardening externally

Component alignment

– shaft alignment up to length of 2500 mm and the maximum diameter of 100 mm.

Suppliers

Contact us

+421 918 811 199

+421 905 772 703

hypromill@hypromill.sk

HYPROmill s.r.o., Teriakovce 10, Prešov 080 05, IČO: 51115484, IČDPH: SK2120595191 Operation: Jesenná 8, Prešov 08005